As a leading manufacturer of stainless steel needles, Sinmer Technology is committed to providing products that are at the forefront of quality and innovation. Our needles are manufactured using state-of-the-art machinery and are subject to rigorous quality control measures. We offer a wide range of stainless steel needles, from thin-walled needles for delicate applications to heavy-duty needles for industrial use. Our manufacturing expertise and dedication to excellence make us the go-to source for stainless steel needles that are reliable and consistent.

Take your efficiency and productivity up a notch with our advanced stainless steel needles at Sinmer Technology. These needles work seamlessly with automated systems and high-throughput workflows to streamline processes which in turn save time, labor and resources. Our precision-engineered tips, uniform dimensions and exceptional durability guarantee reliable performance and consistent results in any production environment even the most demanding ones. Whether you manufacture medical devices; assemble electronic components or fabricate precision instruments – our advanced stainless steel needles will help you do this better than anyone else while still staying ahead of them.

Sinmer Technology knows that every application is different and there isn’t always a one-size-fits-all solution for everyone. That’s why we have our stainless steel needles that can be made to fit any requirement. Whether it’s the length, gauge, tip configuration or surface finish – if you need something specific, our team of skilled engineers will work with you until they create it exactly how you want them too. We can take what’s in your mind and put it into production; no matter if we’re just making prototypes or going all out on production runs – Sinmer has got this covered! Use the Sinmer customizable stainless steel needle when nothing else will cut through hard materials like your project demands.

Sinmer Technology designs dependable stainless steel needles that work the same across all applications. We make them with the best machines and quality control systems at our disposal before testing them rigorously to guarantee top performance and reliability. Our needles are perfect for a research lab where you might be running tests or in a healthcare setting where clinical procedures take place or even an industrial setup producing accurate components among other places; this is because they can be trusted to offer nothing short of consistency and precision necessary for reaching one’s aims. You will always know whether things went well or not if only you were using sinmers’ trusty stainless steel needle – such is their level of accuracy!

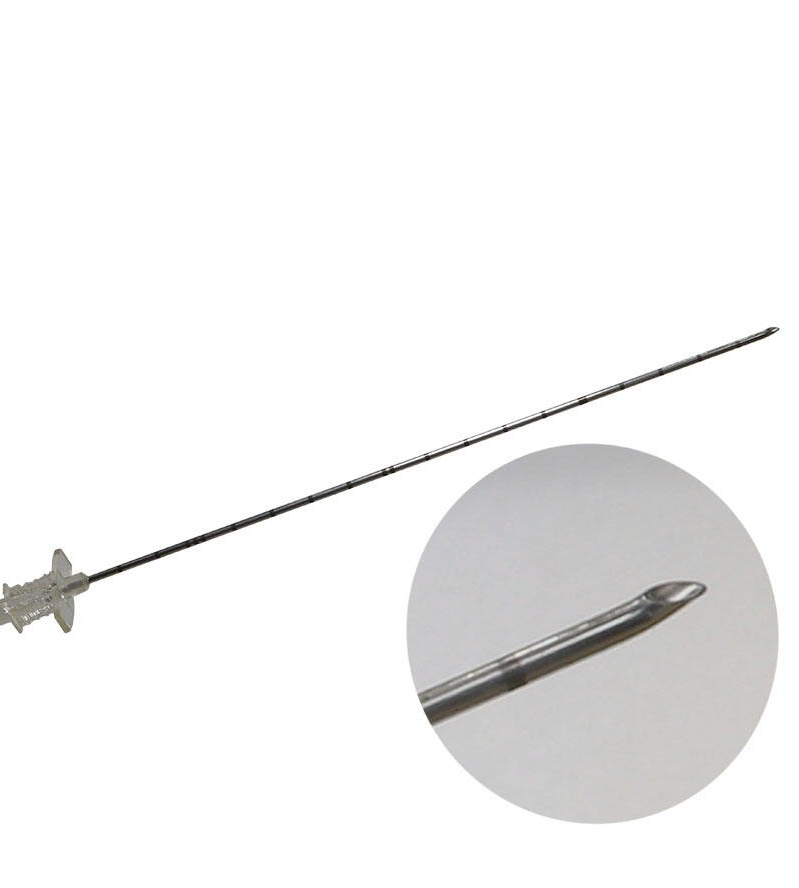

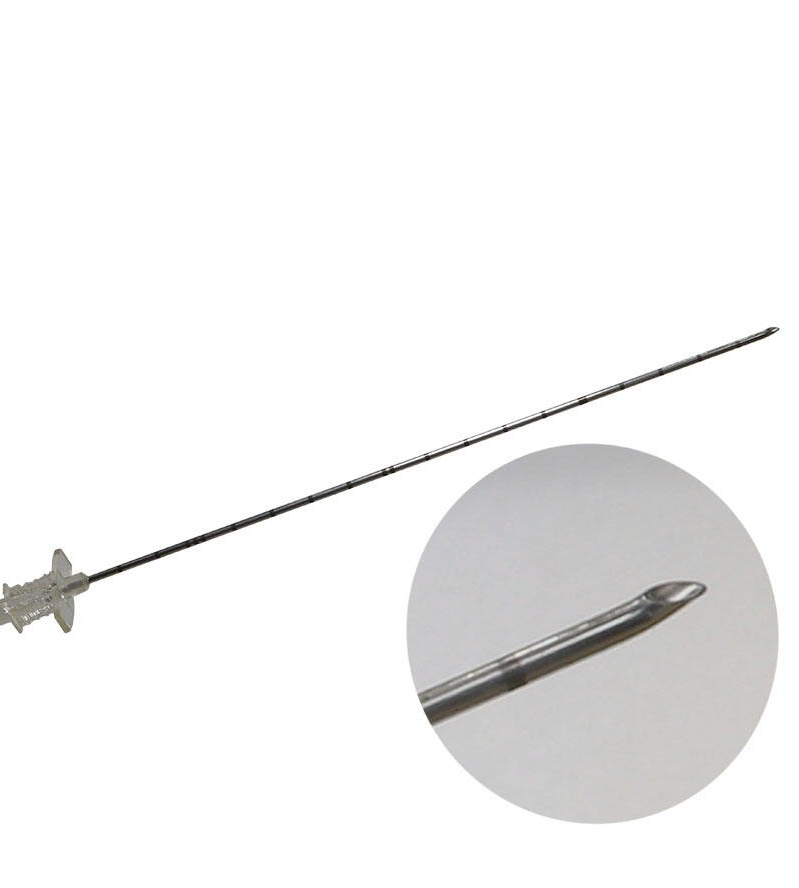

Here in Sinmer Technology, nothing matters more to us than the safety and satisfaction of our patients. For this reason, we have come up with high-quality needles made from stainless steel which are meant to cause minimum tissue trauma while being used in any medical procedure thus reducing discomfort caused to patients. Our needle is made of medical grade stainless steel with ultra smooth surface and a sharp beveled tip that enables easy entry as well as accurate delivery of drugs or fluids into the body system. Additionally these needles possess excellent strength and corrosion resistance properties hence they can still remain intact after several uses without compromising on their functionality thereby giving reliable results consistently. Therefore when it comes to safe, comfortable and hassle free healthcare interventions always go for Sinmer’s top notch stainless steel needle products.

Sinmer a professional OEM manufacturer for micro small metal tubes and solutions to tubing production with more than 15 years' production experience in micro small tubes. The smallest tube can be achieved is OD 0.25 mm and ID 0.09 mm. We can supply micro small stainless steel tubes, brass tubes, aluminum tubes, titanium tubes, carbon steel tubes and assembly parts made of micro small tubes and precision parts.We have professional manufacturing standard process of micro metal tubes, quality control standard procedure, material analysis process, packaging process, and transportation safety process.

Sinmer Technology boasts advanced production processes and impeccable machining techniques, ensuring the delivery of high-quality micro-sized metal tubing products. Our meticulously designed and continuously optimized processes guarantee consistent quality and precision in every tube produced.

We prioritize close collaboration with our clients to provide tailored solutions. Whether it's specific materials, dimensions, or machining processes for industry-specific needs, or custom products for individual projects, we meet our clients' requirements and offer professional technical support and advice.

Sinmer Technology employs rigorous quality control processes, from raw material procurement to production, ensuring that every product meets or exceeds industry standards. We relentlessly pursue excellence, committed to delivering reliable products to our customers.

Our efficient production team and flexible production schedules enable us to promptly respond to customer needs and deliver products on time. Whether it's small batch orders or large-scale production, we can meet our customers' time requirements, ensuring smooth project execution. Sinmer Technology is dedicated to providing high-quality products and services, always putting customers first.

A stainless steel needle is a slender, pointed instrument made of stainless steel, commonly used in medical procedures, crafting, and industrial applications.

Stainless steel needles are known for their durability, resistance to corrosion, and ability to maintain sharpness, making them suitable for various applications.

Stainless steel needles are used in medical procedures like injections, acupuncture, and suturing, as well as in crafting, embroidery, and industrial processes.

Yes, stainless steel needles can be reusable, but proper sterilization is essential to prevent contamination and ensure safety.

Stainless steel needles come in various sizes, ranging from very fine gauge for delicate procedures to larger gauge for industrial use.