When it comes to CNC turning parts, quality is non-negotiable at Sinmer Technology. Our stringent quality assurance processes, coupled with our dedication to precision engineering, guarantee that every part we produce meets the highest standards of excellence. From material selection to final inspection, we leave no stone unturned in ensuring that our customers receive CNC turning parts that are built to last. Choose Sinmer Technology for quality-assured CNC turning parts you can rely on.

Sinmer Technology ensures value is delivered with their cost-effective CNC turning parts. Our high-quality products are priced competitively because we have streamlined manufacturing processes and utilized our skills. This focus allows companies to improve their goods without spending a lot on making them. We want all people to have access to good manufacturing so we offer affordable CNC turning components.

Sinmer Technology’s CNC turning parts have a long-lasting effect, because we believe in long-term dependability. We make our components from strong materials and with cutting edge engineering methods so that they survive tough conditions. If something is built to last like this, then it will be used for many years by the customer without being replaced often which saves money on maintenance fees too.

Sinmer Technology is committed to inventing in the production of CNC turning parts. Every time, we put our money into the most recent developments and surveys to be ahead of other companies. Our Professional employees are always busy with discovering fresh tactics of improving on quality which leads to the production of CNC turning parts that embrace current styles in design as well as latest technological advancement. When you select Sinmer technology, you are choosing a partner who is determined to revolutionize the manufacturing sector through creativity.

Produced by Sinmer Technology, these CNC turning parts are high-performance as they aim at increasing the speed and efficiency of manufacturing. The fastest parts can be produced with our advanced computer numerical controlled lathes which also have the highest precision levels. This implies that we can have them delivered soonest possible just in case you had not figured it yet; even large quantities or intricate projects. For firms wishing to improve their productivity without compromising on quality, this is what will work best for them – high performance cnc turning components from Sinmer technology.

Sinmer a professional OEM manufacturer for micro small metal tubes and solutions to tubing production with more than 15 years' production experience in micro small tubes. The smallest tube can be achieved is OD 0.25 mm and ID 0.09 mm. We can supply micro small stainless steel tubes, brass tubes, aluminum tubes, titanium tubes, carbon steel tubes and assembly parts made of micro small tubes and precision parts.We have professional manufacturing standard process of micro metal tubes, quality control standard procedure, material analysis process, packaging process, and transportation safety process.

Sinmer Technology boasts advanced production processes and impeccable machining techniques, ensuring the delivery of high-quality micro-sized metal tubing products. Our meticulously designed and continuously optimized processes guarantee consistent quality and precision in every tube produced.

We prioritize close collaboration with our clients to provide tailored solutions. Whether it's specific materials, dimensions, or machining processes for industry-specific needs, or custom products for individual projects, we meet our clients' requirements and offer professional technical support and advice.

Sinmer Technology employs rigorous quality control processes, from raw material procurement to production, ensuring that every product meets or exceeds industry standards. We relentlessly pursue excellence, committed to delivering reliable products to our customers.

Our efficient production team and flexible production schedules enable us to promptly respond to customer needs and deliver products on time. Whether it's small batch orders or large-scale production, we can meet our customers' time requirements, ensuring smooth project execution. Sinmer Technology is dedicated to providing high-quality products and services, always putting customers first.

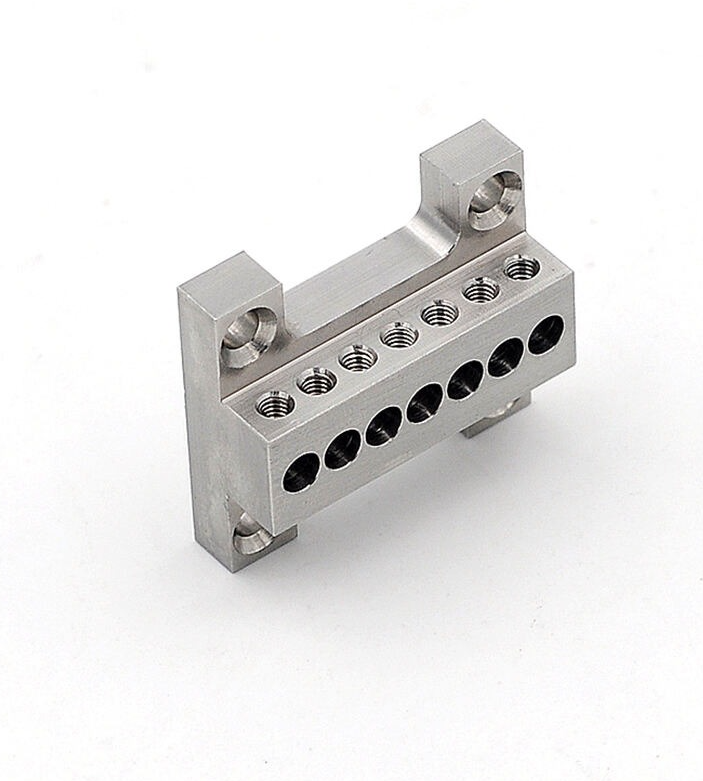

We utilize high-quality metal materials for our CNC turning parts to ensure durability and precision.

Yes, we specialize in providing custom CNC turning parts tailored to our clients' exact specifications and designs.

We employ advanced CNC machining technology and strict quality control measures to ensure the accuracy and precision of every part we produce.

The lead time for CNC turning parts varies depending on the complexity and quantity of the order. Contact us for specific lead time estimates.

Absolutely, our engineering team is experienced in design optimization for CNC turning parts to improve functionality, efficiency, and cost-effectiveness. Contact us to discuss your specific requirements.