Complexity is no obstacle for Sinmer Technology. As your trusted source for CNC turning parts, we thrive on tackling the most intricate and demanding projects. Leveraging our advanced manufacturing capabilities and seasoned expertise, we specialize in producing complex parts with tight tolerances and intricate designs. When you partner with Sinmer Technology, you can rest assured that your most challenging CNC turning part needs will be met with precision and proficiency.

Sinmer Technology takes pride in our sustainable and environment-friendly approach to manufacturing. We know that it is important to make CNC turning parts which do not affect the environment much. Our methods are made so as they produce less waste and use less energy; additionally, we also employ eco-friendly materials wherever applicable. In choosing Sinmer technology, you get excellent quality CNC turning components while at the same time helping an environmentally conscious company grow its roots deeper into future generations’ tomorrows.

Sinmer Technology’s CNC turning parts have a long-lasting effect, because we believe in long-term dependability. We make our components from strong materials and with cutting edge engineering methods so that they survive tough conditions. If something is built to last like this, then it will be used for many years by the customer without being replaced often which saves money on maintenance fees too.

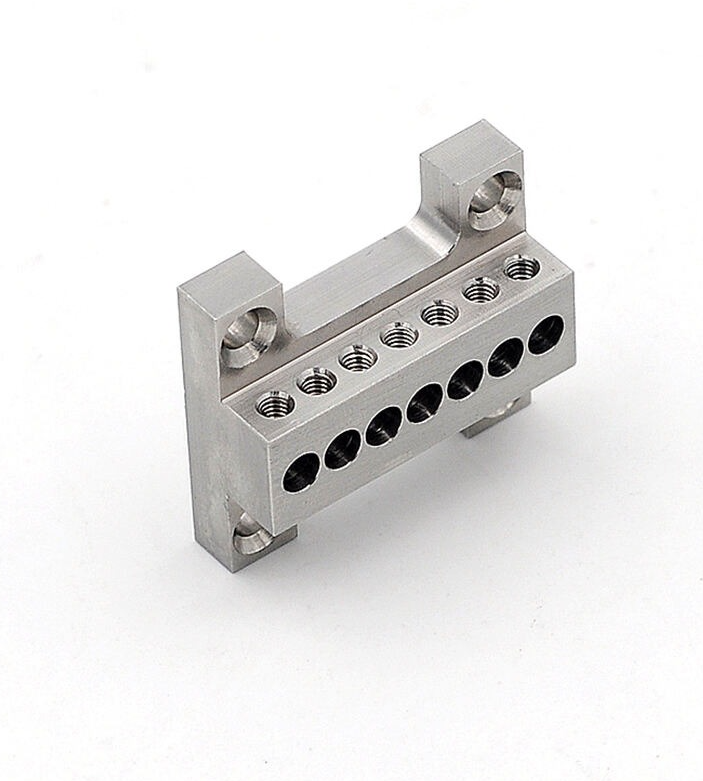

Sinmer Technology is known for its accuracy and quality when it comes to making computer numerical control (CNC) lathe components. We have modern facilities with advanced CNC lathes and turning centers. These machines operated by our skilled machinists can produce parts with precision tolerance. All our CNC turning parts are made according to very precise requirements so as to fit perfectly well in any application that may require them even under extreme conditions. We always show our dedication to accurate machining right from conception through completion of every single piece we manufacture by subjecting them all under strict quality control measures during different stages such as design, production ,and inspection .

No other company can offer the flexibility of Sinmer Technology’s CNC turning parts. These components are used in many industries, so we must be able to meet the requirements for all of them. Our range spans from cars and planes to medicine and electronics; every field has different needs which our products were made for accordingly. We employ engineers who know what each sector demands because they’ve worked with diverse customers before – this knowledge enables us to produce items that will enhance any item’s usefulness or efficiency across a broad spectrum!

Sinmer a professional OEM manufacturer for micro small metal tubes and solutions to tubing production with more than 15 years' production experience in micro small tubes. The smallest tube can be achieved is OD 0.25 mm and ID 0.09 mm. We can supply micro small stainless steel tubes, brass tubes, aluminum tubes, titanium tubes, carbon steel tubes and assembly parts made of micro small tubes and precision parts.We have professional manufacturing standard process of micro metal tubes, quality control standard procedure, material analysis process, packaging process, and transportation safety process.

Sinmer Technology boasts advanced production processes and impeccable machining techniques, ensuring the delivery of high-quality micro-sized metal tubing products. Our meticulously designed and continuously optimized processes guarantee consistent quality and precision in every tube produced.

We prioritize close collaboration with our clients to provide tailored solutions. Whether it's specific materials, dimensions, or machining processes for industry-specific needs, or custom products for individual projects, we meet our clients' requirements and offer professional technical support and advice.

Sinmer Technology employs rigorous quality control processes, from raw material procurement to production, ensuring that every product meets or exceeds industry standards. We relentlessly pursue excellence, committed to delivering reliable products to our customers.

Our efficient production team and flexible production schedules enable us to promptly respond to customer needs and deliver products on time. Whether it's small batch orders or large-scale production, we can meet our customers' time requirements, ensuring smooth project execution. Sinmer Technology is dedicated to providing high-quality products and services, always putting customers first.

We utilize high-quality metal materials for our CNC turning parts to ensure durability and precision.

Yes, we specialize in providing custom CNC turning parts tailored to our clients' exact specifications and designs.

We employ advanced CNC machining technology and strict quality control measures to ensure the accuracy and precision of every part we produce.

The lead time for CNC turning parts varies depending on the complexity and quantity of the order. Contact us for specific lead time estimates.

Absolutely, our engineering team is experienced in design optimization for CNC turning parts to improve functionality, efficiency, and cost-effectiveness. Contact us to discuss your specific requirements.