Experience the pinnacle of expertise in endoscopy bending section technology with Sinmer Technology. With years of mastery in precision engineering and medical device manufacturing, Sinmer sets the standard for excellence in the field. Our team of skilled professionals combines technical prowess with innovation to create bending sections that redefine the possibilities in endoscopic procedures. Trust Sinmer's expertise to elevate your practice and achieve superior outcomes with our endoscopy bending section solutions.

Sinmer Technology’s bending section for endoscopy solutions is the best in terms of quality and performance in the field of medical equipment making. Our commitment to precision engineering and manufacturing is absolute, which is why we keep coming up with new ideas and better ways of doing things so that our accuracy levels are not matched by any other company when it comes to making these components. When you have modern facilities combined with experienced personnel like what exists at Sinmer Technology then one thing becomes clear – nothing can surpass their ability to deliver accurate bending section after another consistently without fail thereby helping you realize higher design ambitions for your medical devices than ever before imagined.

Gain full support and proficiency by working with Sinmer Technology for your endoscopy bending section requirements. Our employees are devoted to giving the best customer service possible by providing help with technology, advising on design and customizing products for your needs. When you choose us as a partner in business you can be assured that all inquiries will be answered quickly; there will always be open lines of communication between us so nothing gets lost or forgotten about during any stage of the project and we will do everything we can think of beforehand to keep things from going wrong in the first place. Have peace of mind while experiencing excellence through our solutions on endoscopy bending sections at Sinmer Technologies.

To ensure compatibility and ease of use, endoscope bending section solutions from Sinmer Technology were designed to achieve seamless integration into medical device systems. The bending section of each instrument is carefully made by our engineers who work closely with customers thereby allowing it fit well with any other existing endoscopic instruments thus saving assembling hours while at the same time increasing productivity. Our products can either be flexible or rigid depending on what you need them for but in either way they will definitely improve the way your equipment works. You will not have any problems incorporating these components into your machines because they were created specifically for this purpose by our team at Sinmer Technology which means that everything should go smoothly without any glitches or errors occurring along the process.

Expand the potential of personalization through our endoscopy bending section solutions at Sinmer Technologies. The team from our engineers department has been working together with customers so as to know what they need and come up with tailor-made bending sections that will fit well into their applications. We provide a wide range of customization options which include choosing materials as well as optimizing design among others thus making sure we cater for different needs in medical devices manufacturing sector. Join forces with us at Sinmer Technology today and let your imaginations be brought into life by using custom made endoscopy bending section solutions.

Sinmer a professional OEM manufacturer for micro small metal tubes and solutions to tubing production with more than 15 years' production experience in micro small tubes. The smallest tube can be achieved is OD 0.25 mm and ID 0.09 mm. We can supply micro small stainless steel tubes, brass tubes, aluminum tubes, titanium tubes, carbon steel tubes and assembly parts made of micro small tubes and precision parts.We have professional manufacturing standard process of micro metal tubes, quality control standard procedure, material analysis process, packaging process, and transportation safety process.

Sinmer Technology boasts advanced production processes and impeccable machining techniques, ensuring the delivery of high-quality micro-sized metal tubing products. Our meticulously designed and continuously optimized processes guarantee consistent quality and precision in every tube produced.

We prioritize close collaboration with our clients to provide tailored solutions. Whether it's specific materials, dimensions, or machining processes for industry-specific needs, or custom products for individual projects, we meet our clients' requirements and offer professional technical support and advice.

Sinmer Technology employs rigorous quality control processes, from raw material procurement to production, ensuring that every product meets or exceeds industry standards. We relentlessly pursue excellence, committed to delivering reliable products to our customers.

Our efficient production team and flexible production schedules enable us to promptly respond to customer needs and deliver products on time. Whether it's small batch orders or large-scale production, we can meet our customers' time requirements, ensuring smooth project execution. Sinmer Technology is dedicated to providing high-quality products and services, always putting customers first.

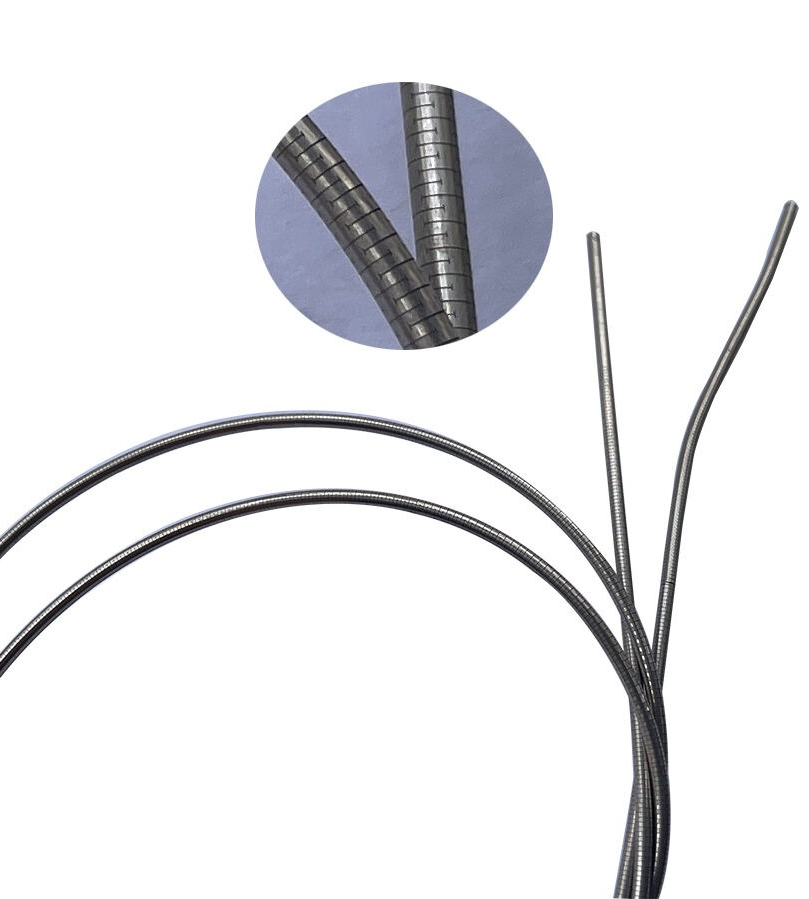

An endoscopy bending section is a crucial component used in endoscopic procedures, enabling flexible maneuverability within narrow or curved passages.

Sinmer Technology specializes in precision manufacturing of endoscopy bending sections using advanced techniques for small-diameter metal tubing production.

Sinmer Technology utilizes high-quality metal materials suitable for medical applications, ensuring durability and compatibility with endoscopic procedures.

Sinmer's endoscopy bending sections are designed to be compatible with a wide range of endoscope models, offering versatility and ease of integration.

The flexibility of Sinmer's endoscopy bending sections allows for smoother navigation through anatomical passages, enhancing visualization and maneuverability during medical procedures.